| Nano Steam Jet Mill | ||||||||||||||||||

+ Fluidized Bed Classifying Jet Mill + Precision Air Classifier + Classifying Impact Mill + Abrasive Powder Classifying Jet Mill/ Shaping + Bag Collector + Ultrafine Powder Processing Line

|

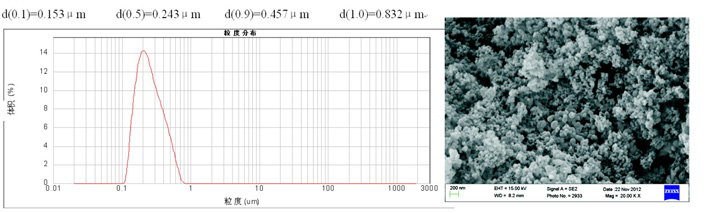

Nano Steam Jet Mill is a newly device by our independent R&D, it uses physic dry-type processing to process Nano powder. High pressure steam makes the material collision each other to perform superfine pulverizing , the finest particles are brought to high temperature bag collector by high precision turbine grader. The spray speed of Nano Steam Jet Mill(1200m/s) is double its original one(500m/s), and grinding strength has increased 4 times, its easy to achieve to nanoscale. Due to steam sonic speed is faster than air speed, it can increase the speed of outer grader blade,and reach the demand of nanoparticles classification. With the advantages of avoid electrostatic aggregation, well dispersion, greatly improved grading efficiency and precision The whole production line is under dry-type processing, dry to sub-micron and nano range , avoid complex working procedure and the high energy consumption of wet-type processing. |

|||||||||||||||||

| ■Application field | ||||||||||||||||||

|

||||||||||||||||||

| ■Main technical parameter | ||||||||||||||||||

|

||||||||||||||||||